Upcycling an old garden shed - or, Building a recycled Log Store.

- iPlantsman

- Nov 22, 2022

- 4 min read

A few years ago, while preparing to move back to Scotland, we lived in a rented house in Crowborough, East Sussex. To store myriad tools and gardening equipment that I have been acquiring over the years, I bought a simple garden shed, with a double front door and one side with a window in it. On moving, we dismantled the shed and it travelled up to Scotland with us on our removal truck.

Since then (some 18 months) it has sat in sections lent up against the side of our house out of sight. That is, until recently, when I decided to kill two birds with one stone (a good way to make a point, but a horrible concept of killing birds). A while ago I decided that I would repurpose the shed posts and panels into a ‘bin tidy’, where I could store waste and recycling bins under cover. This is still the plan, but I had a more pressing need to create a log store for our log burner.

As a useful aid to reduce our need on gas for heating, we have been reinstating a fireplace and installing a high efficiency log burner in our livingroom. Our house was built in 1939 and had originally featured a stove style burner, which over the years of modernisation had been removed and sadly boarded up. I prefer the vintage aesthetic, so had planned to do this before the cost of fuel on a world stage increased so rapidly, in part due to the war in Ukraine, but my timetable has been accelerated because of these factors.

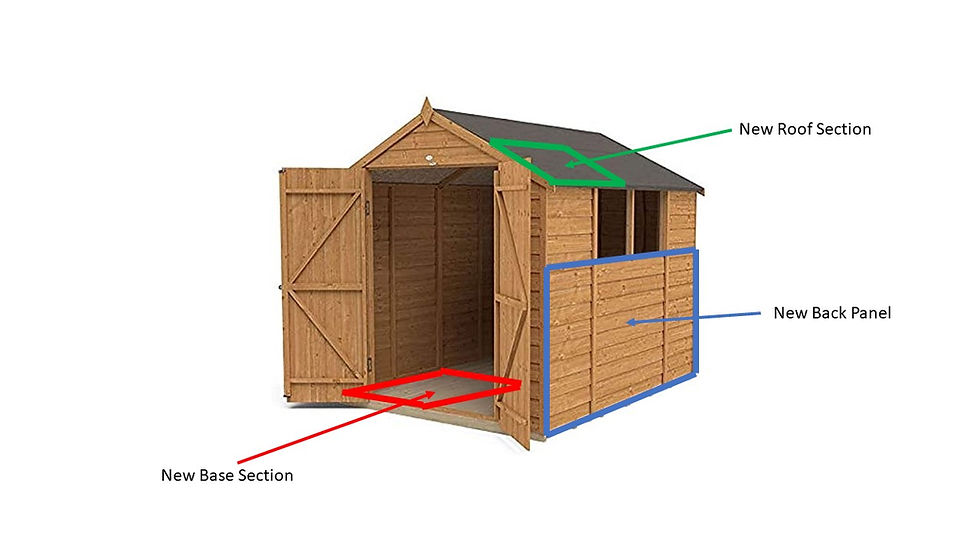

Anyway, a little over a week ago, I started looking at log stores that can be bought from a variety of manufacturers. All good things, but I quickly realised that essentially I already had the parts required to make a log store sat outside. I prepared a very quick mental sketch of sections needed to assemble it (illustrated below) and headed outside with my trusty WORX WX527.1 Cordless Compact Circular Saw to cut out a section of the floor, two sections from either side of the door frame, a section of roof and a section of the panel that had the window.

Using these sections and my WORX WX352 Cordless Drill Driver, some outdoor screws and only a little effort, I assembled the pieces as follows;

I used the section of shed floor as the base to which I attached on opposite ends of the shorter sides the two sections of door frame to form the sides. The door frame sections have a sloped top from the pitch of the shed. I made sure to attach them so that the outward facing slats of the shed continued to face out.

I attached the now windowless section of wall as a back turning it 90° so that the short side now runs along the long side of the base. I attached this to the base and both of the door frame sections. The structure now has some rigidity and would hold log sections, but needs a roof to ensure it can keep the logs dry from falling water.

Finally I attached the roof section to the top. When it was part of the shed, it had been painted to prevent water ingress before the roof felt was attached. The paint and roof felt (facing out) were retained.

To ensure long term success, I checked all the connections and added screws where unions were a little less stable than I had hoped for.

It’s a no frills solution and it won't win any beauty or quality construction awards, but it is functional, hidden out of sight and I’m pretty happy with the result. It took less than 2 hours to make from start to finish, only using two tools. My beloved WORX kit.

Best of all, I still have enough entire sections left to make my bin shelters without needing to purchase additional timber. I will share this project once complete.

I’m a pretty handy diy builder/bodger of things and I enjoy the process. This project was much easier than I expected and a really good use of a resource I already had enabling me to upcycle one unused thing into two that will get regular use. I suspect that I will modify and improve this over time and will shortly refelt the roof, but after just 2 hours of effort, I have a functional log store and it cost me nothing. Now all I need is the logs to fill it!

I have been trialling some axes recently and will write about them shortly.

The Two WORX Tools I used here in this project.

WORX 527.1 Cordless Compact Circular Saw is a really useful power tool, which has proven invaluable on a number of domestic DIY and gardening projects.

WORX WX352 Cordless Combi Hammer Drill. A really useful everyday project drill, as strong as any other cordless drill I have used.

Here is the 6' x 8' shed I cannibalised to make this log store. Forest Fencing Make it, but you will find similar sheds from most manufacturers. It served me well as a shed and will again as a log store and bin shelter.

Of course, if you don't already have an unused shed to cut up and don't want to take on an upcycling project, you can always just buy a similar log store. Here is one of comparable size to mine that would do the job nicely.

Please note, the links to purchase product on this page are paid affiliate link. If you purchase an item, using any of these links I will receive a small payment from them. It doesn't cost you anything and the item is priced as per the normal website price. You can read our affiliate policy here. Links to other websites for information purposes do not benefit me financially and are meant to be informative. I accept no responsibility for the quality, accuracy, or content from third party sites. Thanks

Please note, Images on this page are my own, or labelled with permission from the author/publisher. Forest Shed Images are edited copies of image owned by Forest Garden Ltd. As with all images on this site, they are not for reproduction or use without written permission. Permissions can be sought from emailing hello@iplantsman.com though images of materials copywritten or owned by another party will not be given.

You are so talented, Lewis. I marvel at your ingenuity, creativity and practicality. Fabulous repurposing. X